Nylon Fractional and Metric Tubing

Specifications

- Flexibile

- Good Chemical Resistance

- Low Moisture Absorption

- Superior Dimensional Stability

- Temperature Range: -40°F to +200°F (-40°C to +93°)

- Compare Other Materials

Nylon tubing is a popular choice for low pressure pneumatic applications because of its combination of flexibility and toughness. Nycoil uses a heat and light stabilized, very flexible compound that yields a quality tube. Nylon is the most recommended tubing material for all types of pneumatic circuits.

A circuit designer could never get into trouble using Nylon tubing for pneumatic circuits. Due to its physical properties, Nylon is the number one choice for reliable connections with all types of fittings. Nylon retains its performance integrity in elevated temperatures and generally, because of it's higher pressure and temperature characteristics, Nylon will have a greater flow passage than composite tubing made from other material with the same outside diameter. These factors should never be overlooked when designing pneumatic circuits.

- Low Pressure Pneumatic

- Pneumatic Circuits

- Injection Lube Systems

- Hydro-Pneumatic Circuit

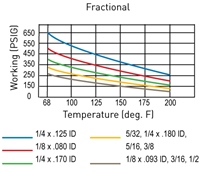

| Nylon Fractional Tubing | ||||||||||||

| Tube O.D. |

Tube I.D. |

Wall

Thickness |

Part Number | Min. Bend Radius |

Weight | Working Pressure |

Burst Pressure | Color Code | ||||

| 100' | 500' | 1000' | ||||||||||

| inch | inch | inch | Reel | Reel | Reel | inch | 1000' (lbs.) | psi @68°F | psi @125°F | psi @68°F | Suffix Key | |

| 1/8 | .080 | .023 | 6121_ | 6521_ | 6021_ | 1/4 | 3.3 | 500 | 350 | 1500 | 0 = Natural 1 = Black 2 = Red 3 = Blue 4 = Green 5 = Yellow 6 = Orange 7 = Gray |

|

| 1/8 | .093 | .016 | 6122_ | 6522_ | 6022_ | 1/2 | 2.5 | 267 | 187 | 800 | ||

| 5/32 | .106 | .025 | 6123_ | 6523_ | 6023_ | 5/8 | 4.8 | 333 | 233 | 1000 | ||

| 3/16 | .137 | .025 | 6133_ | 6533_ | 6033_ | 3/4 | 5.8 | 267 | 187 | 800 | ||

| 1/4 | .180 | .035 | 6144_ | 6544_ | 6044_ | 7/8 | 1.9 | 333 | 233 | 1000 | ||

| 1/4 | .125 | .062 | 6146_ | 6546_ | 6046_ | 1-1/4 | 16.9 | 667 | 467 | 2000 | ||

| 1/4 | .170 | .040 | 6147_ | 6547_ | 6047_ | 7/8 | 12.2 | 400 | 280 | 1200 | ||

| 5/16 | .232 | .040 | 6155_ | 6555_ | 6055_ | 1 | 15.7 | 333 | 233 | 1000 | ||

| 3/8 | .275 | .050 | 6166_ | 6566_ | 6066_ | 1-1/4 | 23.3 | 333 | 233 | 1000 | ||

| 1/2 | .375 | .062 | 6188_ | 6888_* | 6088_ | 2-1/4 | 39 | 267 | 187 | 800 | ||

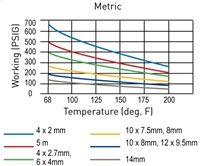

| Nylon Metric Tubing | ||||||||||||

| Tube O.D. |

Tube I.D. |

Wall

Thickness |

Part Number | Min. Bend Radius |

Weight | Working Pressure |

Burst Pressure | Color Code | ||||

| 100' | 500' | 1000' | ||||||||||

| mm | mm | mm | Reel | Reel | Reel | mm | 1000' (lbs.) | psi @68°F | psi @125°F | psi @68°F | Suffix Key | |

| 4 | 2.7 | .65 | 7104_ | 7404_ | 7704_ | 24 | 3.8 | 367 | 257 | 1100 | 0 = Natural 1 = Black 2 = Red 3 = Blue 4 = Green 5 = Yellow 7 = Gray |

|

| 4 | 2 | 1 | 7102_ | 7402_ | 7702_ | 24 | 6.8 | 667 | 467 | 2000 | ||

| 5 | 3 | 1 | 7105_ | 7405_ | 7705_ | 30 | 9 | 500 | 350 | 1500 | ||

| 6 | 4 | 1 | 7106_ | 7406_ | 7706_ | 36 | 11.2 | 400 | 280 | 1200 | ||

| 8 | 6 | 1 | 7108_ | 7408_ | 7708_ | 48 | 15.8 | 283 | 198 | 850 | ||

| 10 | 8 | 1 | 7111_ | 7411_ | 7711_ | 60 | 22.0 | 200 | 140 | 600 | ||

| 10 | 7.5 | 1.25 | 7110_ | 7410_ | 7710_ | 70 | 24.6 | 267 | 187 | 800 | ||

| 12 | 9.5 | 1.25 | 7112_ | 7412_ | 7712_ | 70 | 31.0 | 233 | 163 | 700 | ||

| 14 | 12 | 1 | 7116_ | 7416_ | - | 100 | 29.1 | 133 | 93 | 400 | ||

| 16 | 13 | 1.5 | 7119_ | 7419_ | - | 115 | 48.2 | 145 | 101 | 435 | ||

| Part Number | |

| Tube Cutter | 60001 |

- Corrosion resistant hardened steel blade assures straight, crisp cuts for optimum fitting connection

- Replacement blades can be installed in seconds using only a screwdriver