Composite Push-to-Connect Tube Fittings

Plug-In Reducer - Metric

Composite Push-to-Connect Advantages

This fitting was designed to meet the needs of the motion control industry where fast assembly, dis-assembly and re-assembly is important. No special tools needed for tube assembly, just insert the tubing until it bottoms.

Composite Push-to-Connect is designed to be used without a tube support, providing full flow through the tubing. The grab ring design grips the tubing securely to provide retention.

Composite Push-to-Connect external pipe threads come with a preapplied white PCTFE sealant. Positional external pipe threaded ends are featured on shapes for installion in compact areas and for precise positioning.

Specifications:

This fitting was designed to meet the needs of the motion control industry where fast assembly, dis-assembly and re-assembly is important. No special tools needed for tube assembly, just insert the tubing until it bottoms.

Composite Push-to-Connect is designed to be used without a tube support, providing full flow through the tubing. The grab ring design grips the tubing securely to provide retention.

Composite Push-to-Connect external pipe threads come with a preapplied white PCTFE sealant. Positional external pipe threaded ends are featured on shapes for installion in compact areas and for precise positioning.

Specifications:

- -4ºF to +175ºF at up to 290 psi depending on tubing being used.

- Vacuum applications are dependent upon temperature and type of tubing being used.

- Tube sizes are determined by the number of sixteenths of an inch in the tube O.D.

Composite Push-to-Connect fittings were designed as an economical alternative for pneumatic applications. Ready to use, compact,one-piece fitting for use with most thermoplastic tubing.

Composite Push-to-Connect shaped fittings have a composite body with nickel plated brass componentry.

| Materials | ||

| Component | Material | |

| Body | Glass Reinforced Nylon 6.6 | |

| Collar | Nylon | |

| Gripping Ring | Stainless Steel | |

| D Seal | Nitrile | |

| O-Ring | Nitrile | |

| Base | Nickel plated brass with Thread sealant on tapered components and captive seal on parallel threads | |

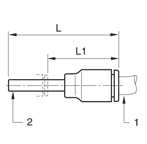

| Plug-In Reducer - Metric | ||||

| Tube O.D. 1 |

Tube O.D. 2 |

Length L |

Length L1 |

Part Number |

| mm | mm | mm | mm | |

| 4 | 6 | 37.5 | 23.5 | P124252 |

| 4 | 8 | 37.5 | 19.0 | P124253 |

| 4 | 10 | 44.0 | 22.5 | P124254 |

| 6 | 8 | 37.5 | 20.0 | P124264 |

| 6 | 10 | 38.0 | 17.5 | P124265 |

| 6 | 12 | 46.0 | 23.0 | P124266 |

| 6 | 14 | 48.0 | 23.0 | P124267 |

| 8 | 10 | 49.0 | 28.5 | P124269 |

| 8 | 12 | 49.0 | 24.5 | P124270 |

| 8 | 14 | 48.0 | 23.0 | P124271 |

| 10 | 12 | 56.5 | 33.5 | P124273 |

| 10 | 14 | 58.5 | 33.5 | P124274 |

| 12 | 14 | 58.5 | 33.5 | P124276 |